Get clear batch, date, & logo prints on dark surfaces with our multi-color white ink printers. Easy to use, low cost, printable anywhere. Explore solutions now!

Beyond Black: Why Your Industrial Coder Needs White Ink Capability

🎨 Beyond Black: Why Your Industrial Coder Needs White Ink Capability

In the food industry, compliance is non-negotiable. Every package must clearly display Batch Numbers (BN), Manufacturing Dates (MFG), and Expiration Dates (EXP). But for many products, the packaging itself presents the biggest hurdle, especially when dealing with dark packaging, colored bottles, or transparent films. Your brand deserves visibility, and your codes must be legible—regardless of the substrate color.

The Challenge of Dark Substrates

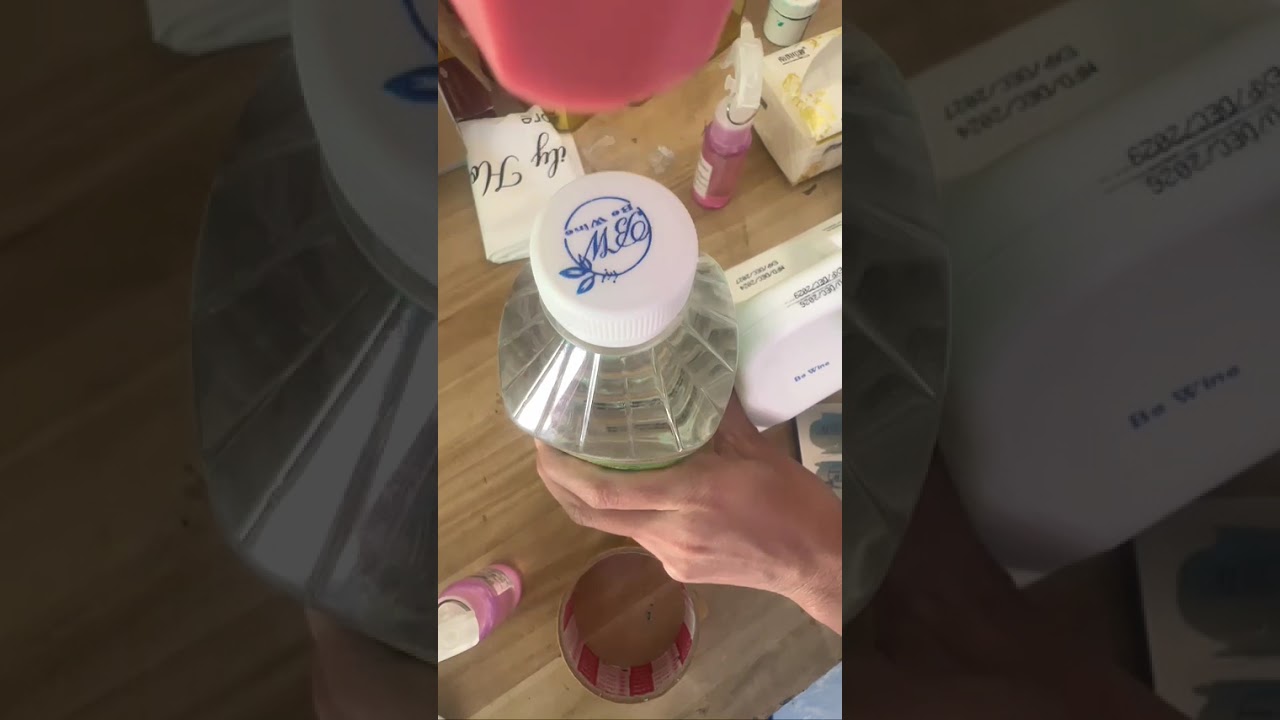

We recently encountered a perfect example with a valued client in Africa whose product required clear batch codes and branding on dark, distinct packaging. Standard inkjet systems simply could not meet the requirement; they were confined to black ink only. The resulting code contrast was poor, jeopardizing regulatory compliance and the product's premium appearance.

In today's global market, relying on a single color for coding is no longer competitive. Manufacturers need flexibility.

✨ Unlock Complete Color Versatility

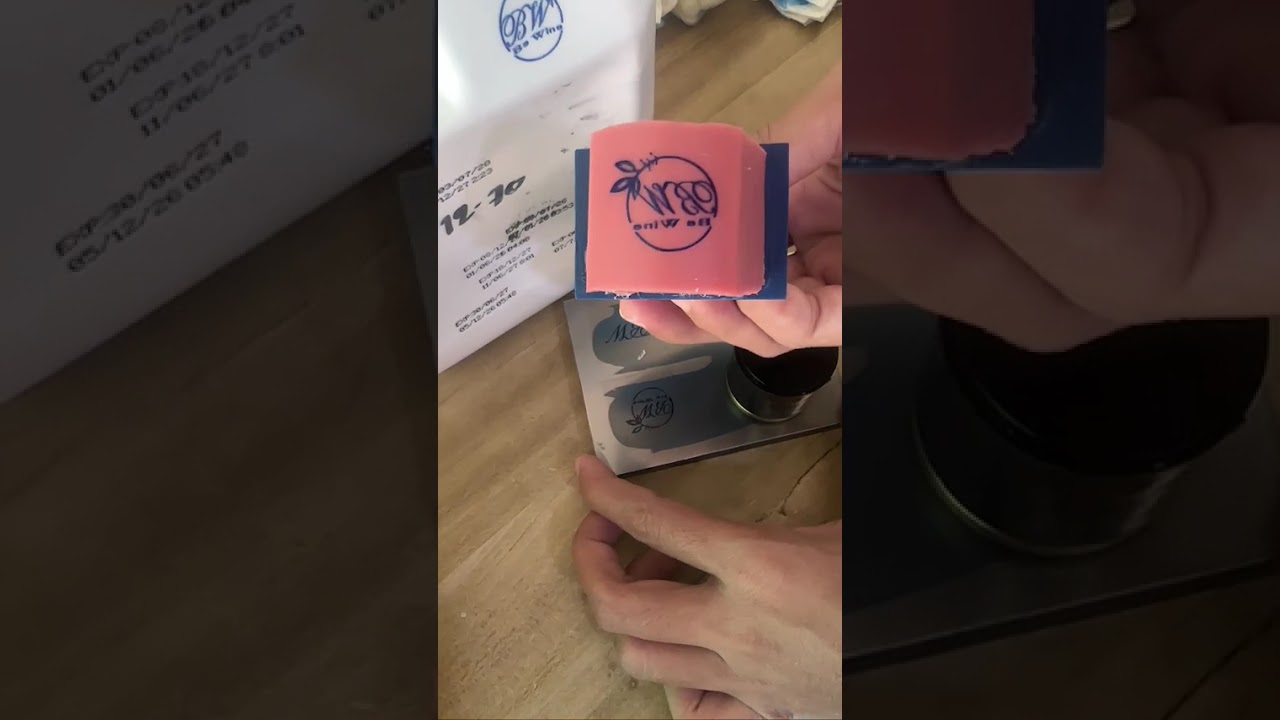

This is where advanced printing technology provides the competitive edge. Our high-performance coding equipment breaks the "black-only" barrier, offering complete color versatility, including a vibrant, opaque white ink.

White ink is a game-changer for several reasons:

- Maximum Contrast: On dark blue, red, or black materials, white ink provides the highest possible contrast for immediate readability and accurate scanning.

- Branding Consistency: It allows you to maintain brand guidelines even in the coding area.

- Material Versatility: Our system ensures that this specialized white ink adheres flawlessly to any material—from dark plastics and metals to challenging transparent surfaces.

From Problem to Perfect Print

Our printer not only delivered the demanded white print for the African client but also proved its ability to switch colors and substrates instantly. This capability means you can standardize your coding equipment across diverse product lines, reducing inventory and training costs.

Why accept limitations? If your product demands high-contrast marking, it's time to upgrade to a coding solution that offers the full spectrum of color choice. White ink printing is no longer a luxury—it's essential for clear traceability and superior product presentation.

Related Articles

One Tool to Print Your Logo on Everything (Bottles, Caps, Bags & More) Many business owners ask: "Do I need different machines for different products?" The answer is NO. Whether your product is a roun

Quick Tip: How to Print Your Logo on Small, Curved Bottle Caps (Easy Way) Putting your brand's logo directly onto small bottle caps is a great way to look professional. But try to print on a tiny, cur

Pro Tip: Get Your Own Custom Logo on Golf Balls (The Mark Won't Scratch Off!) If you're running a golf tournament, promoting a brand, or just want a cool gift, putting your own custom logo on golf bal