Coding Soft Cosmetic Paper Boxes

Protecting Your Brand: A Technique for Flawless Coding on Soft Cosmetic Boxes

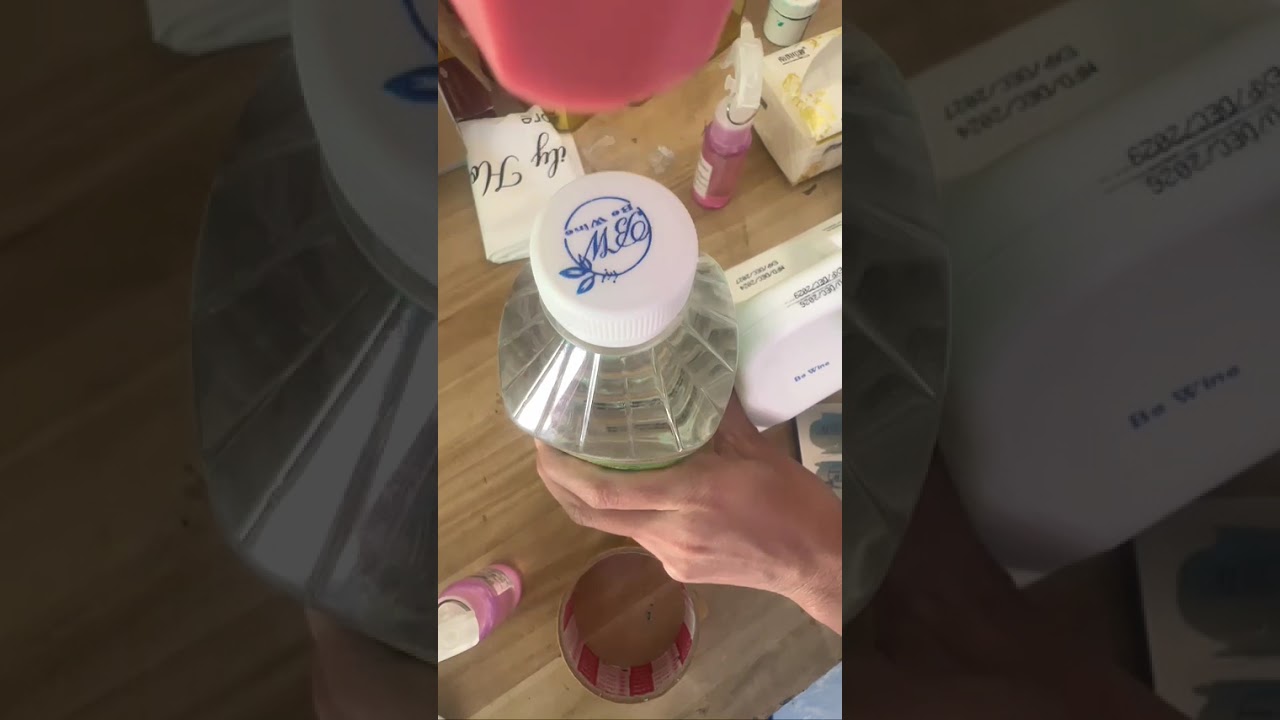

In the cosmetics industry, the final presentation of the packaging is as crucial as the product itself. However, applying necessary batch and expiry dates often presents a dilemma: the required codes must be permanent, but the paper boxes are often soft, lightweight, and lack rigid support underneath.

Using standard hand stamps or even light automation on soft, glossy cardboard frequently results in box crushing, indentations, or ink smearing, instantly compromising brand image. This challenge is unique to the cosmetic and high-end retail sectors.

The Solution: Controlled Pressure Marking

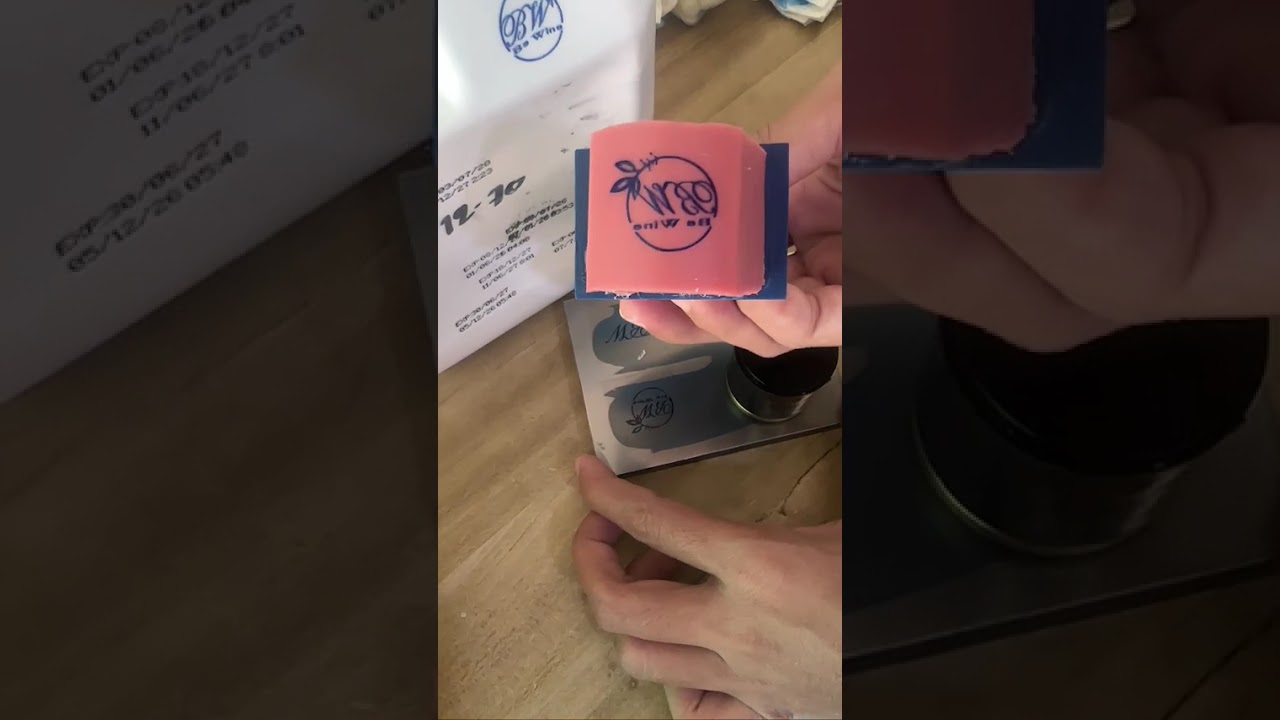

This tutorial shares a specialized technique that addresses this specific Cosmetic Packaging Coding problem. The key is using an industrial stamper engineered for **controlled, minimized pressure**. Unlike bulky traditional coders, this tool applies only the necessary force to transfer the fast-drying ink without deforming the soft paper box.

This method ensures the packaging remains pristine while delivering a crisp, high-contrast code. It's the most reliable, low-CAPEX way to achieve compliance without damaging the aesthetic integrity of your product.

Compliance and Traceability Benefits:

- **Maintains Aesthetics:** Codes are applied cleanly on glossy or coated paper, preserving the high-quality look of the box.

- **Full Compliance:** Guarantees legible MFG/EXP/Batch traceability, essential for regulatory audits.

- **Cost-Effective:** Eliminates the need for expensive, high-speed automated systems that are overkill for small and medium batches.

- **Zero Smudge:** The specialized ink adheres instantly to cosmetic packaging materials, preventing rub-off.

By implementing this specialized technique, your team can ensure every unit leaves the facility with both flawless codes and an undamaged package. To explore the tools that master soft packaging, visit our website today.

For personalized advice on marking difficult materials, contact us via WhatsApp: +66 62 031 6162.

Related Articles

One Tool to Print Your Logo on Everything (Bottles, Caps, Bags & More) Many business owners ask: "Do I need different machines for different products?" The answer is NO. Whether your product is a roun

Quick Tip: How to Print Your Logo on Small, Curved Bottle Caps (Easy Way) Putting your brand's logo directly onto small bottle caps is a great way to look professional. But try to print on a tiny, cur

Pro Tip: Get Your Own Custom Logo on Golf Balls (The Mark Won't Scratch Off!) If you're running a golf tournament, promoting a brand, or just want a cool gift, putting your own custom logo on golf bal