How to Code Bumpy Bubble Mailer Seams

Logistics Challenge Solved: The Technique for Coding Bumpy Seams on E-commerce Packaging

Traceability is critical in logistics, but coding on shipping materials like bubble mailers presents a unique difficulty. Not only is the surface inherently uneven due to the air bubbles, but the most logical place for the code is often the seam or interface—a spot with significant thickness differences and extreme surface variation.

Traditional coding methods, including handheld inkjet printers, struggle to maintain print quality when encountering these drastic high and low points. The codes often smear, smudge, or are partially illegible, creating compliance risks and slowing down warehouse operations.

Mastering the Extreme Unevenness

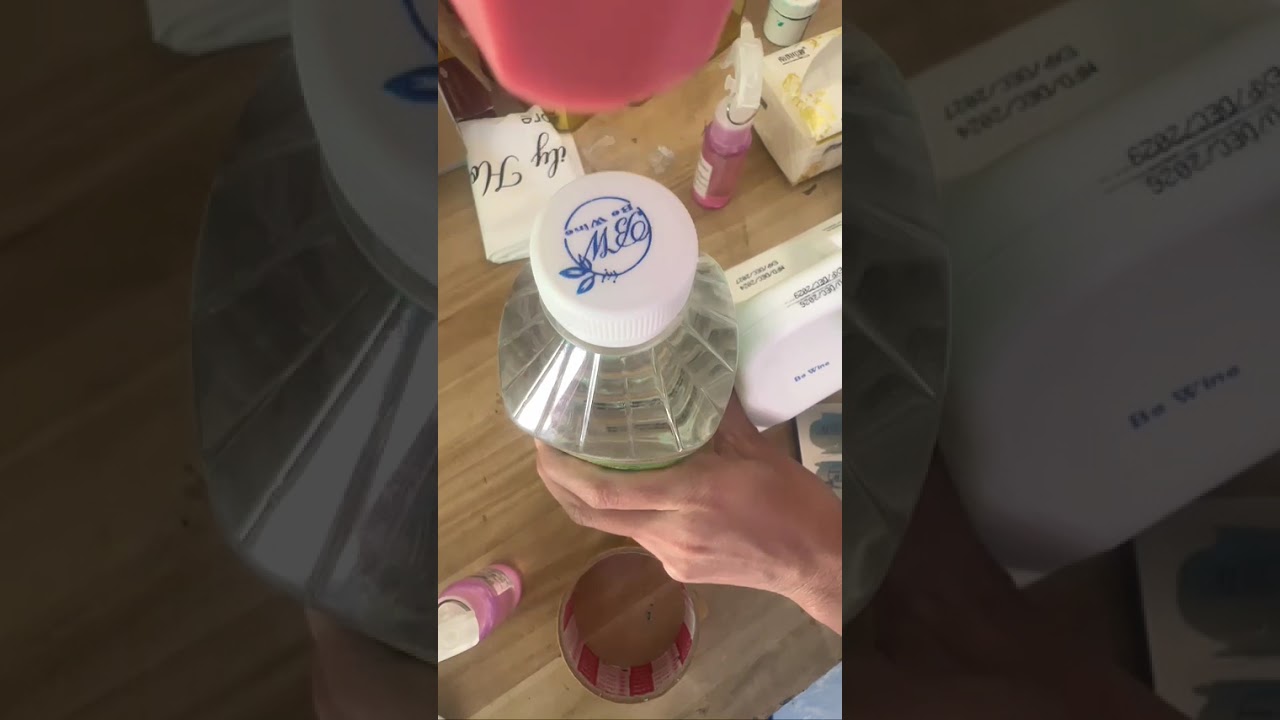

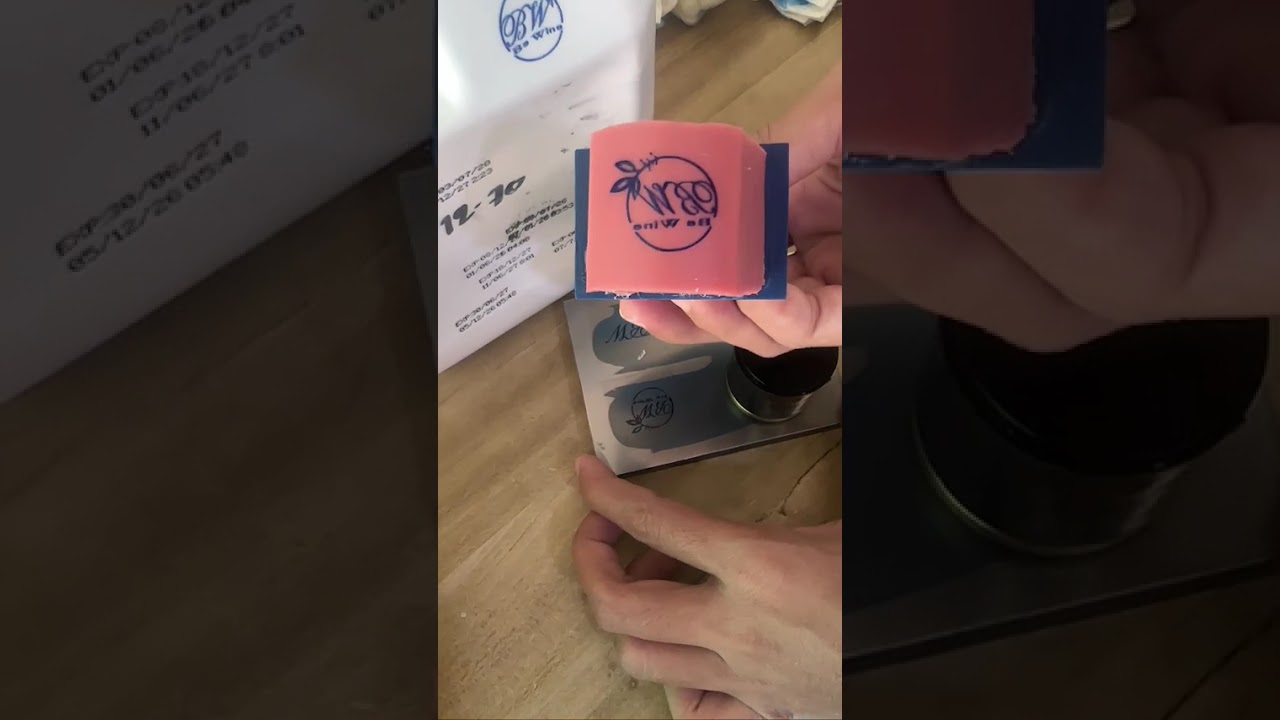

The solution is a specialized industrial stamper designed to compensate for these high-low surface variations. Unlike non-contact coders, this tool works by ensuring complete, compliant transfer of ink across the most challenging surfaces, such as the thick, bumpy plastic seams of a bubble mailer.

This technique relies on instant-adhesion ink formulated specifically for flexible plastics. The process is simple, allowing warehouse teams to quickly and reliably mark batch numbers, date codes, and internal tracking IDs without worrying about crushing the packaging or dealing with smudges.

Key Benefits for Logistics & E-commerce Coding:

- **Conforms to Bumps:** Flawlessly codes across extreme irregularities and thick seams without skipping or smearing.

- **Durable Traceability:** Codes adhere instantly to the plastic and resist handling damage in the supply chain.

- **Low CAPEX:** A cost-effective alternative to automated systems, ideal for operations that need speed and flexibility.

- **Simple Operation:** Zero training time required; the tool is reliable and easy for any warehouse staff member to use.

If your e-commerce business needs to upgrade its logistics packaging coding on irregular materials, this technique provides the necessary durability and consistency. For a versatile, low-cost solution, explore our full range of uneven surface marking tools on our website.

For direct advice on marking difficult materials, contact us via WhatsApp: +66 62 031 6162.

Related Articles

One Tool to Print Your Logo on Everything (Bottles, Caps, Bags & More) Many business owners ask: "Do I need different machines for different products?" The answer is NO. Whether your product is a roun

Quick Tip: How to Print Your Logo on Small, Curved Bottle Caps (Easy Way) Putting your brand's logo directly onto small bottle caps is a great way to look professional. But try to print on a tiny, cur

Pro Tip: Get Your Own Custom Logo on Golf Balls (The Mark Won't Scratch Off!) If you're running a golf tournament, promoting a brand, or just want a cool gift, putting your own custom logo on golf bal